Design Services

Crafting Your Vision into Reality

At Southern Engineering Solutions, our Design Services aim for a cohesive and united approach towards completing your project. Our process is simple yet effective - we analyze your manufacturing requirements, recommending layout solutions that lead to processing efficiencies, yield improvements, and resource reductions.

This is achieved through an established partnership with our clients and subcontractors and our excellent working relationship with dependable manufacturers and automation specialists.

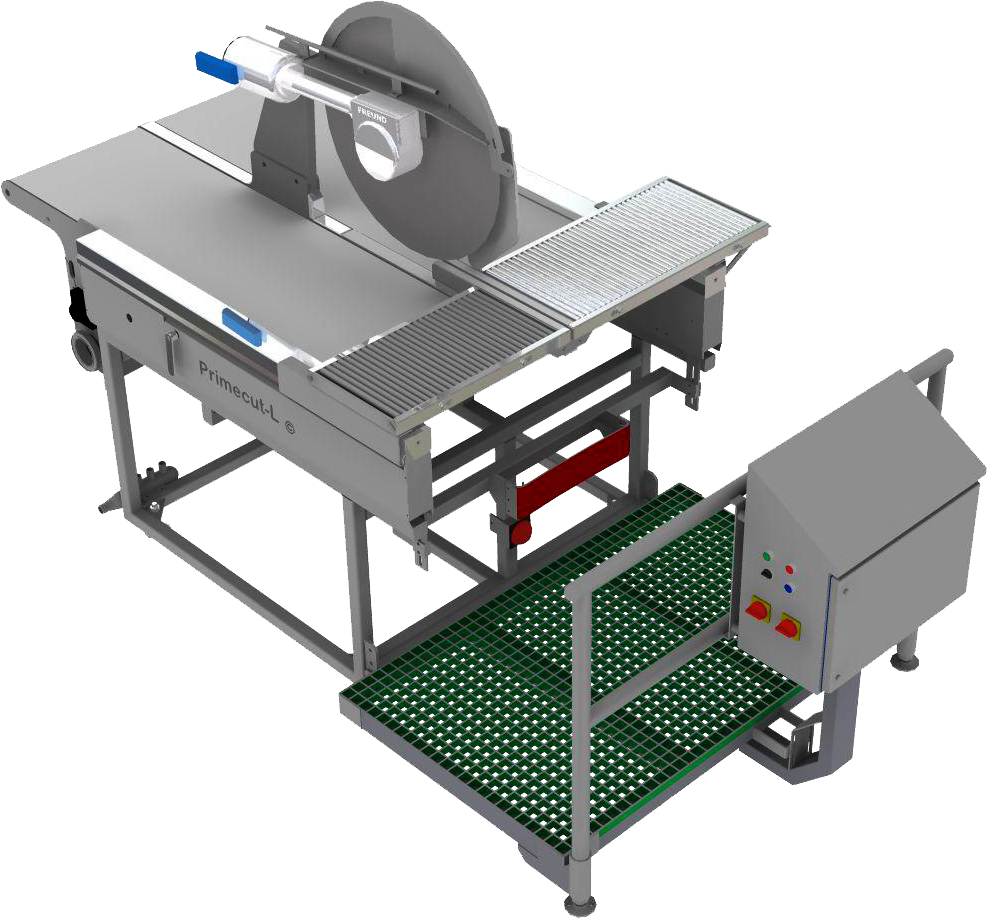

Our design process is clearly outlined in four stages: Issues and Options Study, Budget and Presentation, Full Design and Manufacture, and Installation and Commissioning. We also ensure that all our designs are presented in easy-to-understand 3D CAD drawings, clearly visualising the completed project.

What Sets Us Apart:

- Client-Centric Collaboration: We pride ourselves on forging partnerships with our clients, ensuring that our designs resonate with their aspirations.

- Trusted Industry Alliances: Our longstanding collaborations with leading manufacturers and automation specialists guarantee seamless, innovative solutions.

- Record of Excellence: Our portfolio speaks volumes. With a history of delighted clients, we invite you to join our list of successful collaborations.

- Precise Requirement Analysis: By understanding your manufacturing needs deeply, we design systems that enhance efficiency, optimize yield, and save resources.

- Visual Clarity: We convert complex engineering concepts into easy-to-grasp 3D CAD visuals, ensuring everyone is on the same page regarding the project's trajectory.

Our Detailed Approach

Entrust your vision to SES and watch us meticulously craft it into an engineering masterpiece. Your success is our mission.

Stage 1:

Discovery & Drafting

- Site assessment to pinpoint existing issues.

- Review of present-day processes and layouts.

- Thorough audit of meat cuts, associated processes, and end points.

- Gauge existing spatial dimensions and equipment utility.

- Collaborate with plant managers to crystalize project objectives.

- Preliminary 2D layout sketches for proposed changes.

- Proceed to next stage post client sign-off.

Stage 2:

Visualization and Validation

- Transcend to 3D spatial visualizations of the endorsed proposal.

- Draft presentation-ready documents inclusive of 3D CAD designs.

- Detailed budget estimations for the proposed enhancements.

- Pitch to the board and seek affirmation before advancing.

Stage 3:

Blueprint to Build

- Craft meticulous mechanical drawings to guide manufacturing.

- Rigorous reviews with client management to ensure alignment.

- Coordinate with equipment manufacturers for impeccable project culmination.

Stage 4:

Implementing Excellence

- In-house assembly and testing within our state-of-the-art workshop.

- Onsite assembly and testing to ensure perfect alignment.

- Celebrate the success post client endorsement of the completed project.

Elevate Your Engineering Experience

Elevate beyond the ordinary. Reach out to us and experience the pinnacle of stainless steel fabrication.

Contact Us

We will get back to you as soon as possible.

Please try again later.

At SES, we fuse innovative mechanical engineering with unmatched expertise in the food industry and conveyor systems. Based in New Zealand, our dedicated team pioneers quality design solutions tailored to elevate productivity and ensure client satisfaction. Partner with SES — where cutting-edge technology meets world-class engineering.

Quick Menu

Address Details

Physical Address:

496 Waterloo Rd, Islington,

Christchurch 8042, New Zealand

Postal Address:

PO Box 11023, Sockburn

Christchurch 8443, New Zealand

Office Enquires

Call us direct:

Email direct:

Website created by

BoldType Creative

SEO by: YouTubeAdGuru

Nelson | West Coast | Christchurch | Timaru | Otago | Dunedin | Southland | Bluff | Northland | Whangarei | Auckland | Waikato | Hamilton | Bay Of Plenty | Tauranga | Napier | New Plymouth | Levin | Wellington Gisborne | Invercargill | New Zealand

All Rights Reserved | Southern Engineering Solutions Ltd, Christchurch, New Zealand.